Backlash… What it is and How to minimize it.

When you take a nut, thread it onto a rod you and can feel the movement as you push and pull the nut while keeping it from turning, that slight movement is backlash. It is the result to the manufacturing tolerances required that allow a nut to move along the threaded rod without binding. All CNCs that use incorporate this design will encounter backlash..

When you take a nut, thread it onto a rod you and can feel the movement as you push and pull the nut while keeping it from turning, that slight movement is backlash. It is the result to the manufacturing tolerances required that allow a nut to move along the threaded rod without binding. All CNCs that use incorporate this design will encounter backlash..

What can be done about it?

- Don't worry about it. If the backlash is small, and you are making parts that the tolerances are not critical, then this might be a good option. This can be an inexpensive method, and most CNC software will compensate for backlash.

-

Preload the nut. There are many ways to do this. I will give you three of these:

- Make the nut out of UHMW and cut the threads slightly smaller in diameter than the rod. If the nut is long enough ( 1 to 1.5"), it will have enough error that backlash will be minimal, however, the nut fits snug and takes some effort to turn. This means part of the motor’s torque has to be used to turn the nut. Therefore, the top speed may suffer. When these wear out, they will need to be replaced as there is no adjustment.

- Make an acetal nut and use a spring and tapered cone to clamp the threads in the radial direction. This method is the same as using 2 half nuts that are being squeezed around the threaded rod. The advantage to this method is that they tend to be self adjusting until the spring expands enough not to be in compression. The disadvantage is that with high accelerations the spring will compress for a small amount of time, causing a small error, until the backlash assembly can catch up.

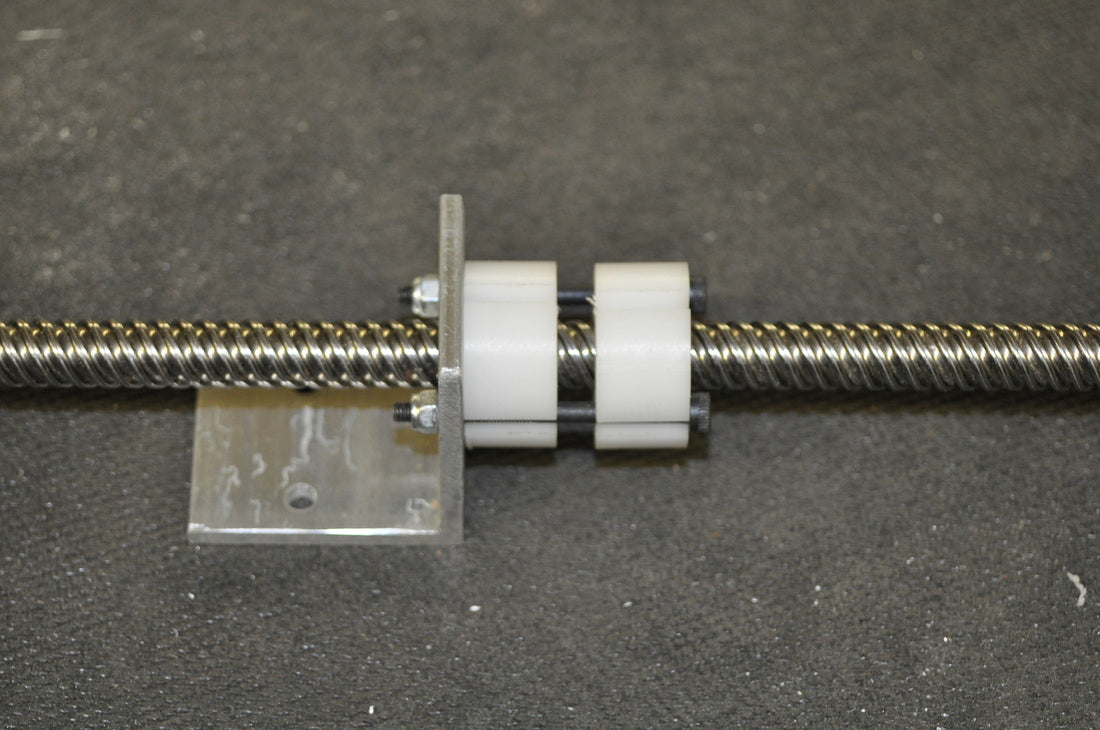

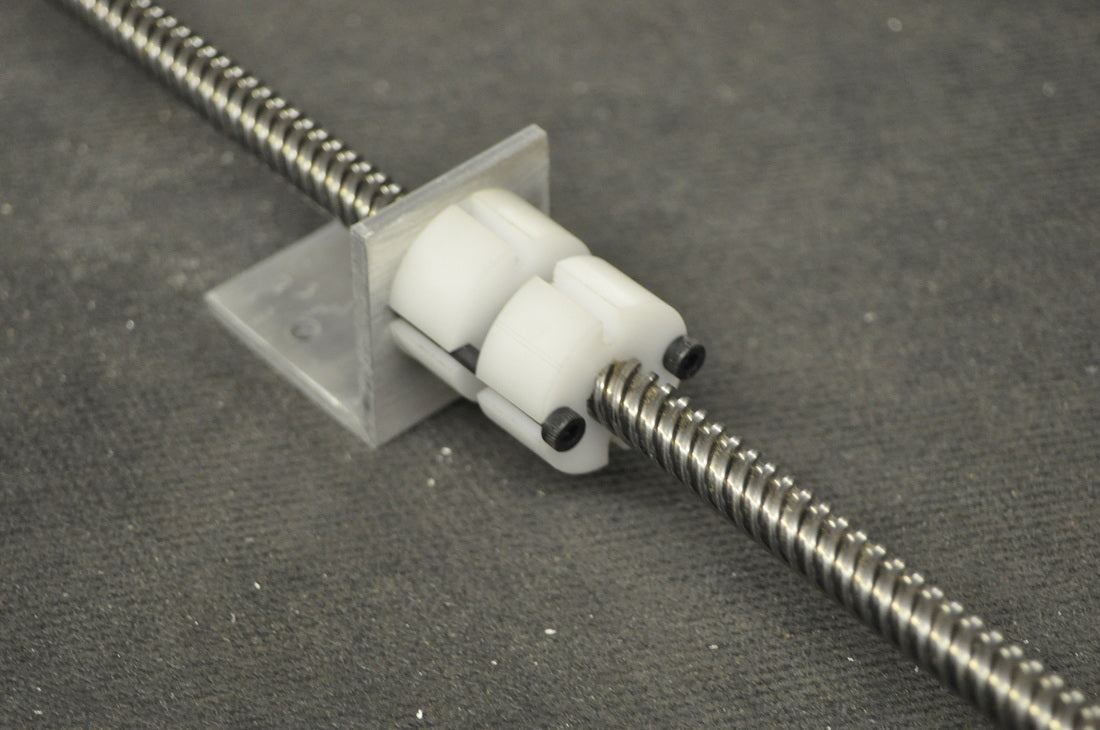

- Make two acetal nuts and use compression or tension to axially hold them apart. This is the method I have used for my machines. One nut’s threads work in one direction, the other nut’s threads work in the opposite direction. We are only using one side of the threads of each nut. It needs to be manually adjusted periodically. For me, this design is simple and cost effective.

- Ball screws. This is a great method to minimize backlash with minimal loss in torque. The disadvantage is that these can be expensive. This is one of the products that you truly get what you pay for.

It is expensive to make parts with very small tolerances. All CNC routers on the market have errors in areas that can include lead screws, bit defection, Micro-stepping, and lack of rigidity.