Customer Project Gallery - old version

3D Elephant Wall Art

Created by: Martin Allen

Machine: E4 CNC Router

Material: 1/8" Baltic Birch Plywood

Bits, Speeds and Feeds: 1/16th end mill bit only. Speed 40 ipm and 0.04 depth of cut.

Door Harp

Created by: Ralph Elmore

Machine: E3 CNC Router

Material:

Base: 1" x 12" select pine

Sound Board: 1/4" cabinet grade birch plywood.

Speeds, Feeds, & Bits:

1st cut: (pocket) (15 ipm plunge x 20 ipm feed) (.10" cut depth per pass) (.25" stepover) = .50" dia. 1/4" shank flat end mill x depth of .20". For the sound board inlay.

2nd cut: (pocket) (15 ipm plunge x 20 ipm feed) (.10" cut depth per pass) (.25" stepover)= .50" dia. 1/4" shank flat end mill with start depth of .20" and cut depth of .35". For the sound hole pocket

3rd cut: (profile on the line) (20 ipm plunge x 25 ipm feed) (.10" cut depth per pass) = 1/4" shank x 60 degree v-bit x .18 cut depth. For the flower outline

4th cut: (profile on the line) (20 ipm plunge x 25 ipm feed) (.10" cut depth per pass)= 1/4" shank x 60 degree v-bit x .18 cut depth. For the flower outline

5th cut: (profile inside the line) (20 ipm plunge x 25 ipm feed) (.06" cut depth per pass) = 1/8" flat end mill x .35 deep. For the shaker pegs

6th cut: (profile inside the line) (20ipm plunge x 25 ipm feed) (.06" cut depth per pass) = 1/8" flat end mill x .6875 deep.for the zither pins.

7th cut: (profile on the outside of line) (20 ipm plunge x 25 ipm feed) (.06" cut depth per pass)= 1/8" flat end mill x .76" depth. Cuts out the flower.

Living Room Table Tray

Created by: Will Harlan

Machine: E4 CNC Router

Material: Wavy Maple

Bits, Speeds and Feeds:

60-degree V-Bit: Speed: 16000 rpm Feed: 45 in/min

1/4" End Mill Speed: 10000 rpm Feed: 60 in/min

1 1/4" Surfacing Bit (RC-2245) Speed: 15000 rpm Feed: 40mm/sec

Toddler Rocking Chair

Created by: Theron Culp

Machine: KL744

Material: Birch

Bits Used: 1/8"

Speeds and Feeds: 120 ipm 60, plunge .1

Letter Board Bench

Created by: Eddie Kazmerchuk of Woodchuk's Custom Creations

Machine: KL744 CNC Router

Wood: Pine

Bits Used: .250 Endmill, 90Degree Vbit, and 1/8 Straight bit

Speeds and Feeds: Thomas cut using .250 endmill .1dwpth per pass and 100ipm. Followed by a profile path using a 90vbit at .125 flat depth and 75ipm finally a profile cut using 1/8 straight bit at 200ipm.

Inlay Cutting Board

Created by: Shawn McKinney of HokieMade

Machine: E4 CNC Router

Wood: Walnut with Movingui Stripes

Inlay Wood Type: Canarywood

Size: 19"L x 12.5" W x 1.25" Thickness

Bit: 1/16 straight cut bit

Speeds and Feeds: 35 ipm, .030” depth of cut

Oval Rose

Created by: BlackWolf CNC Woodworking

Machine: E4 CNC Router

Material: Select Pine

Roughing: .25 EM Feed Rate 60

Finishing: 3.175mm Ball Nose Feed Rate 50

Profile: .12 EM Feed Rate 60

Viking Ship with Frame

Created by: Kjell Evensen of Evensen Productions

Machine: E4 CNC Router

Wood:

Viking Ship: Cherry

Frame: Walnut

Size:

Viking Ship: 7.25" x11.00"

Frame: 10.25" x14.00"

Bits:

Roughing: 3.175mm end mill

Finishing: 1mm tapered ball nose

Speeds and Feeds

Roughing: 1mm pass depth and started with 35 ipm and went slowly up to 150%.

Finishing: Started at 40 ipm and went up to 200% for the Viking ship and 150% for the frame.

911 Dispatcher

Created by: Chase VanderWege of Wege Wood Works

Machine: E3 CNC Router

Bit: 75mm tapered ball nose

United States of America

Created by: Matt Lett of Matt's Heroic Woodworks

Machine: E4 CNC Router

Wood: Oak

Bit: 90 Degree V Bit

Feed Rate: 4"per minute

Honor

Created by: Andy Anderson

Machine: E4 CNC Router with DC Spindle

Wood: Popular

Bits, Speeds and Feeds:

.25" end mill for roughing and profile cuts. The finish cut was done with a 3.175 mm 4.15 degree .5 mm tip tapered ball nose cutter, 20 IPM with 8% stepover. Engraving was with a .25 60 degree V-bit.

Finish: Danish oil finish, followed by a dark stain on the rock areas. Finally fished with a satin urethane.

Remember Flag

Created by: Chase Vander Wege of Wege Wood Works

Machine: E3 CNC Router

Wood: White Oak

Thickness: 1 inch

Speeds and Feeds:

90v bit .06 depth per pass at 35ipm

.125 endmill .06 depth per pass 10% stepover and 40ipm.

Cutout with .25 endmill .06 depth per pass at 35ipm

POW MIA Flag

Created by: Andrew Ritz of Torched Wood Works

Machine: E Series

Wood: Pine

Size: 16"x 11.5"

Bit: 90° vbit

Feed Rate: 50

Marine Coin Display Rack

Created by: Andrew Ritz: Torched Wood Works

Machine: E3 CNC Router

Wood: Premium Pine

Bits:

90 Degree V-bit for Starts

60 Degree V Bit for Logo

30 Degree V Bit for Lettering in Scroll.

Speeds and Feeds:

50 feed rate, 20 plunge, and .06 depth per pass

90 degree v-bit/.25 depth

60 degree v-bit/.025 depth

30 degree v-bit/.015 depth

Nursery Name Plaque

Created by: Heidi Nelson of D&H; Holler Designs

Machine: E4 CNC router

Wood: 3/4 Pine, planed down to 1/2 inch.

Bits:1/8 in. double spiral down flute end mill

Speeds & Feeds: Feed rat started at 20 to cut the centers and then increased to 40 with the UGS over ride.

Spartan Knife Block

Created by: Greg Grote

Machine: E4 CNC Router

Wood: Purple Heart

Bits:1/8" 2-flute straight bit for everything except the "G", which was 90° x 1/2" vbit

Speeds and Feeds: 20 ipm, 0.045" depth per pass

Welcome

Created by: Chase VanderWege of Wege Wood Works

Machine: E3 CNC Router

Wood: Walnut

Bits, Speeds and Feeds:

Rough Cut : 125.4 Flute Ball Nose @ 58ipm @.06 depth per pass

Finish Cut: .5mm tapered ball nose @75 ipm, 6% stepover.

The Lord's Supper

Created by: James Rodriquez

Machine: E3 CNC Router

Wood: White Pine

Size: 10.5" x 5.5"

Bits: 125 end mill rough, & .1 ball nose finish

Speeds and Feeds: 20 ipm for both

Horse Plaque

Created by: Jim Hofer

Machine: E4 CNC Router

Wood: Pine

Bit: Rough Cut 1/4 ball nose end mill

Speeds and Feeds: 1/16 depth ,60 ipm

Bit: Finish Cut: 1mm tapered ball nose

Speeds and Feeds: at 25 ipm for finish.

Bit: Cut Out, 1/4 end mill for cutout.

Finish: Stained with golden pecan and sprayed with clear shellac.

Ganesha

Created by: Nickolas & Deepti Bogert

Machine: E4 CNC Router

Wood: Hard Maple

Size: 14" x 21" x1.5"

Bits:

Roughing 1/4" Endmill

Finishing 1/16" Tapered Ball Nose

Speeds and Feeds:

Roughing: .0625" depth of cut. 35 ipm with a 40% step over.

Finishing: 20 ipm with a 10% step over.

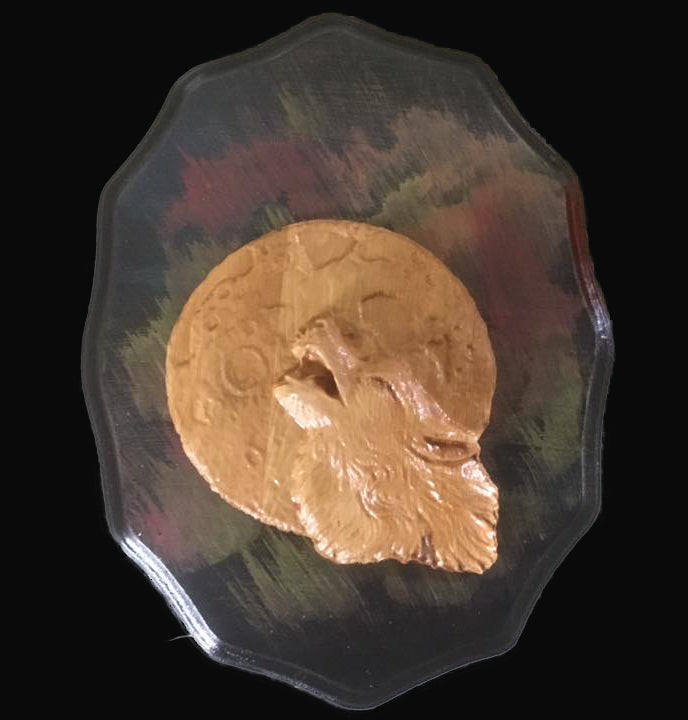

Wolf and Moon

Created by: Don & Liz Fry

Machine: E3 CNC Router

Wood: Pine

Size: 12x7” thickness .75”

Rough Cut:

Bit: 6.16 mm end mill

Speeds and Feeds: pass depth 3.0 mm stepover 0.616 mm (10%) Spindle speed 12000 rpm feed rate: 540 mm/min

Finish Cut:

Bit: 6mm ball nose diameter 4.0 mm

Speeds and Feeds: stepover 0.4 mm offset climb Spindle speed 12000 rpm feed rate 20”/min plunge rate 8.0”/min

54" Ultra Stick

Created by: Charlie Fite

Machine: E4 CNC Router

Wood: Balsa and ply construction,

Bits: 1/16" 2 flute straight end mill

27000 RPMs, 30-40 ipm.

Dragon Frame

Created by: Tim Joy of TJ's Custom Carvings

Machine: E3 CNC Router

Wood: Poplar

Wood Piece: 13x15x1.875

Surfaced Wood Piece: Surfaced down to 1.125 with a 1.000 surfacing bit at 20 ipm x 6pr x .050 dpi

20 ipm, 8 pr, and .050 dpi on roughing code 1/4 em

20 ipm 6 pr. and 0.30 dpi on finishing cut 1.0 r engraving bit.